Flex in a wood/rawhide tree

We are no longer building saddle trees, but we have two videos about how Western saddles fit horses available on our westernsaddlefit.com website.

There have been a couple interesting internet conversations lately asking the question on whether a rawhide covered wood tree will flex and why. This is sometimes stated as a “pro” for rawhide compared to fiberglass covered trees. Since I took so much time thinking about and writing up our responses there, I figured I could make a blog post out of it. So here’s our take on “flex” and rawhide covered wood trees…

Does a rawhided tree flex? Sure. So does a fiberglass covered tree, tall buildings, steel beams and concrete. Everything flexes to some degree, though often it takes very sophisticated equipment to measure how much. To figure out what really happens on a horse may very well be impossible. However, there are other questions about this that maybe should be considered.

Do we even want a tree to flex and if so, how much? If the question is if a tree will either bend or break, then yes, we would want bend. (I’ll get back to that one.) But if the question is flex to move with the horse, our answer is no, we don’t want that. How can something that flexes enough to “move with the horse” not sag under the rider’s weight, putting excess pressure in the center of the saddle? They do. The advent of the “flex trees” has shown this is the case. (Here’s a blog post with the proof of that.)

Do we want a tree to flex when roping? The idea that the tree will take some of the stress and not transmit it to the horse may sound good, but you don’t want a lot of flex then either. Good bars are designed to have edge relief, etc. so there are no high pressure points on the horse. Now, if the tree gives, where and how much pressure is it putting on the horse? Something that flexes a lot when the cow hits the end of the rope could have a lot of “dig” on the edges of the bars in the direction of the pull and could “pinch” a lot too. That is NOT when you want your horse to be reacting to pain! You want that pressure spread out as much as possible over the entire surface area of the tree.

But when you hear experienced saddle makers talking about how they see problems with the ground seats being pulled away from the fork in well used working saddles, you realize that there has to have been some movement over time for that to happen. So, assuming the wood component of the trees were identical (which is an impossibility because every section of every piece of board is different), which covering would stand up to repetitive strain best? You can’t bend fiberglass very far or very often before it breaks and loses all strength at one time. However, you can bend a piece of rawhide back and forth and back and forth and back and forth, etc. etc. etc. for a long time before you see wear on it. And it loses strength gradually with repetitive strains. It takes a LOT of pressure to totally rip it, if it is good rawhide of a decent thickness. (We grant that “chicken skin” tears much more easily…)

In fact, people sometimes don’t realize their tree has broken because the rawhide holds it in place. Here’s the description of what we discovered on a tree we had in to duplicate where the rawhide had held the bars together when the wood appeared to have been broken for a while. Now, do you want to be riding a tree like this? No. It will “flex” in the middle and those broken bar ends will put a lot of pressure on a horse’s back. But is that better than having the whole thing disintegrate underneath you when you are holding a bull? You better believe it. Just don’t ride it again the next day…

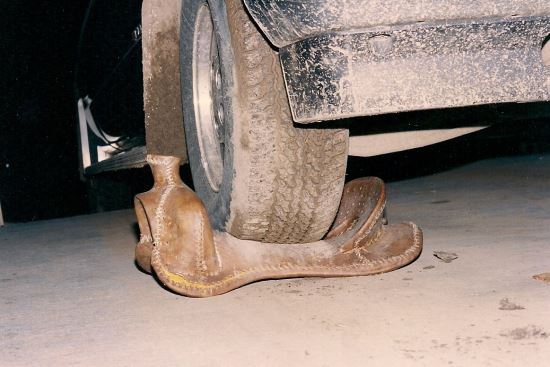

Another example of how well rawhide on its own flexes is our experiment in driving over one of our trees early on in our tree making career. It was a tree we decided wasn’t up to snuff and we weren’t going to send it out, so we decided to see what it would take to break it. The front end of a small truck didn’t do it…

Neither did the front end of a half ton…(The split laces on the left front bar are where we cut them to check out the tree better prior to testing it.)

But the front end of a loaded five ton moving truck driven over the center of the bars flattened them to the ground with nasty cracking sounds. After the truck drove off, those bars were back to their original shape. The stitching had given in a couple of places on each bar, and it was scuffed all along the bottom edge of the bar, but it was back to normal. And push and pull on that tree as we might, we could not make it budge.

We soaked it for a few days to get the rawhide soft enough to remove and discovered that the yellow poplar we had made the bars from had cracked longitudinally in three places on one bar, twice on the other, through the screw holes where the bar attached to the fork where the wood is thinnest. The cracks didn’t extend all the way to the back of the bars. (Sorry, no pictures. This was before the age of digital cameras…) The rawhide had flexed down to the ground and come back to shape, and still was more than strong enough to hold its original shape. Fiberglass would have been broken and finished. So yes, in cases of extreme stress, we feel that rawhided trees will tolerate more flex than fiberglassed trees.

But, can you honestly compare between trees? Not really, because every piece of wood is different, every piece of rawhide is different, and there are multiple kinds of fiberglass and other synthetics which are all different, and how they are laid up makes a difference as to how well they hold up also. It honestly comes down to the quality of the materials – wood and rawhide or other covering – and those vary dramatically between makers. We believe that rawhide will hold up longer and better than the synthetics. We know that rawhide can hold up for over a 100 years (lots of old saddles with rawhided trees are still around) but it will take another few decades to know if fiberglass stands up the same…

So to sum up, we don’t believe good quality wood/rawhide trees should or do flex under regular riding, though rawhide does have the ability to withstand long term, repeated stress (ie. heavy roping) better than fiberglass coverings do. And we also feel that good quality rawhide is better at withstanding short term, high level stress (ie. wrecks) as well. At least, that is our opinion on the matter, and so that is what we will continue to use on our trees.

For those interested in reading more, here's the link to the rest of the discussion on Leatherworker.net.