Angles - it just isn't that simple

We are no longer building saddle trees, but we have two videos about how Western saddles fit horses available on our westernsaddlefit.com website.

When people discuss saddle fit and try to label trees or saddles to describe their fit, you can get into a real quandary. The old Quarter Horse, Semi-Quarter Horse and Full Quarter Horse labels are so inconsistent that they are not very useful. (We wrote about that before.) Now people like to talk angles, figuring that saying 90 degrees or 93 degrees will mean that all trees with that label will fit the same. Nope. T’aint so…

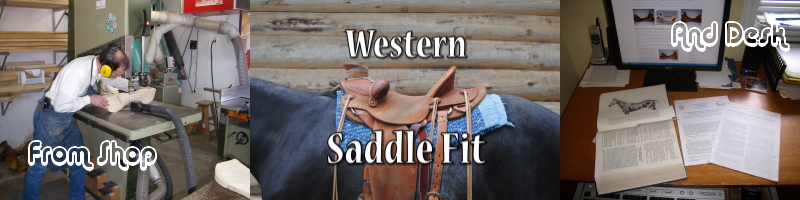

We have written about this before, explaining why the numbers of bar angles are meaningless between makers, but let’s try another way. When we talk 90 degrees, all we are describing is the angle we mark on the back of the bars. (And even that changes as we talk about in the bar angle page.) Let’s call this Angle #1. This angle changes with fit for the horse, but also with fork angle - in the way we build our trees anyway.

Now we cut out the fork, but the table is tilted at another angle. Let’s call that Angle #2. That angle changes depending on the fork angle – how much it is stood up or leaned ahead. And these angles vary between makers as well.

|

|

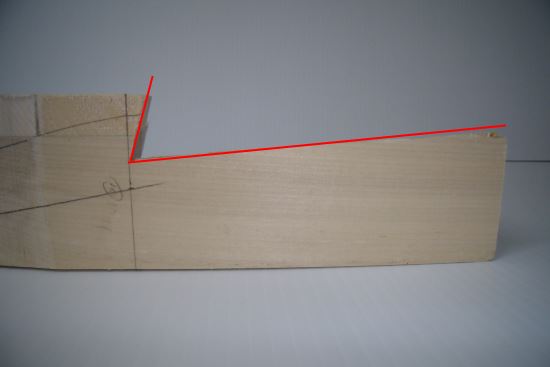

And as we show here, when you add a second angle, 90 degrees suddenly isn’t “90 degrees” any more. Yes, the square is still at 90, but the “practical angle” is different. And the more angles you have to include, the more “practical” it becomes…

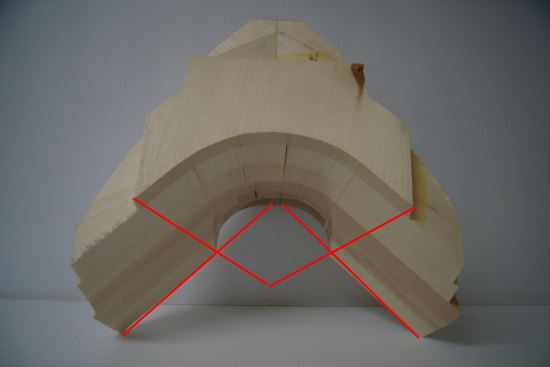

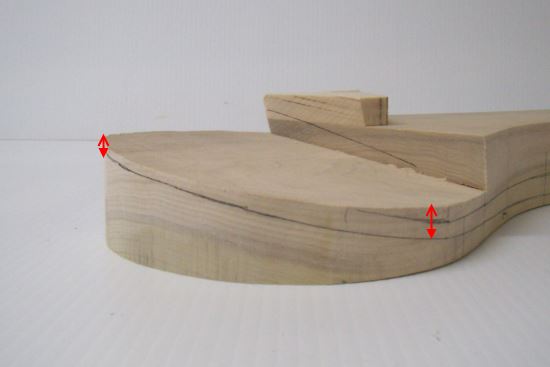

OK, let’s look at the bars. On the side of the bars we mark two more angles. We’ll call the more vertical Angle #3 and the more horizontal Angle #4. The more vertical angle changes with fork angle and the more horizontal angle will change with amount of rock we put in the bars. Note, not every tree maker does it this way. We all do things differently. But it is also important to realize that all these angles are different between makers as well…

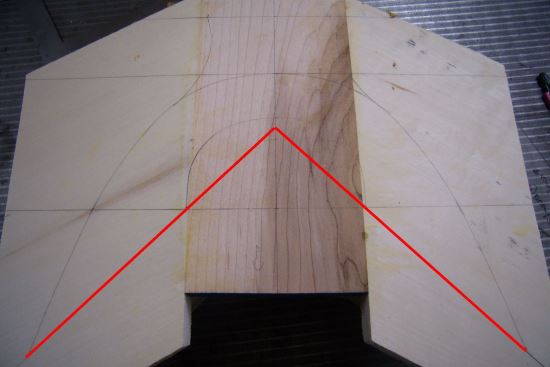

Now lets put the bars in the jigs we use to cut them out. The jigs set the angle of the bars relative to the horizontal front to back – Angle #5...

And relative to the horizontal side to side – Angle #6. And we have three sets of jigs which change these angles depending on fork angle. A fourth set is for pack trees. Oh, and every tree maker likely has different angles on their jigs as well...

Next we start marking out the bars. Even though the bar is cut at an angle (imagine that!), what we mark for the bottom doesn’t match that angle – Angle #7. Why? The bottom and the top of the bar form a sharp edge on the inside of the fork because they need to meet flush there. But we need it thicker on the outside to provide enough relief so the bar edge doesn’t dig into the horse. And, you guessed it, every tree maker marks out their bars differently as well.

We haven’t even started on the shaping and how that affects things yet. And we're only talking the front here, not the twist, or rock or crown...

Bottom line, “90 degrees” is a label, not a measurement. And every maker's 90 degree bars don’t fit the same. Sort of like QH, Semi-QH, Full QH...