If they only knew what was inside...

We are no longer building saddle trees, but we have two videos about how Western saddles fit horses available on our westernsaddlefit.com website.

We got another tree in to duplicate lately. I feel for the owner on this one. The story is that less than two years ago, he paid $4300.00 for a plain roughout with a padded seat from a shop with a good reputation that, from our understanding, contracts out building saddles to individual saddle makers. This past autumn, a horse rolled on it. No flipping over backwards or major fall on hard ground. Something the saddle maker said shouldn’t break a tree. When the customer went back to the store for warranty work, they told him because he was a rancher and worked cattle on pasture, it wasn’t covered...

This is what was showed up at our shop.

The leather is good quality. (We ask for all the leather that goes on the tree to be sent to us when making duplicates. It helps us make sure it will go on the new tree well.) The workmanship on the saddle overall looks good, with the exception of the evidence of multiple screws poking through the bottom of the bars…

But what was underneath the leather was… not good, to put it mildly.

A tree of this quality fits into what we affectionately call the “chicken skin and knotty pine” category. Basically, the rawhide is so thin and poor that it just ripped, while the staples easily pulled out of the light weight pine. If this is the quality of tree used in strength comparison tests with synthetic coverings, no wonder people go for the synthetics...

Here is the thickness of the rawhide – somewhere between 1/32” and 1/16” depending on the area of the tree we measured.

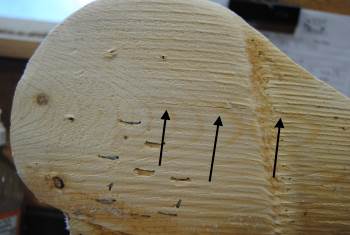

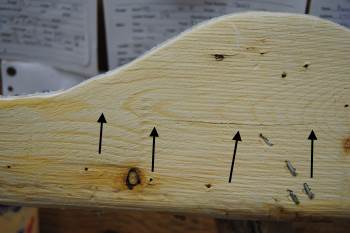

The quality of the wood is no better. Multiple knots in the pine, including a huge one right in the center of the bar at the thinnest part.

|

|

It had knots in the cantle and the fork too.

|

|

In checking out the rest of the tree, the bars hadn’t broken across – the stress wasn’t that great – but both had cracks in them lengthwise

|

|

When we checked out the bottom of the bars, they didn't match. The right one was quite flat, while the left one was actually concave. We wondered if it was just the rawhide making the difference, but nope – they look just like this in the wood too.

|

|

So we checked out the front bar pads. You can see the different amounts of crown between them as well when compared to one of our patterns. By the way, that is our “really flat” crown pattern, and these bar pads are flatter than that…

The other thing we found interesting was how sharp the edges were on the bottom of the bar. The top were rounded nicely for the rider’s leg, but the bottom had a pretty dramatic edge on it.

You can see the effect of those sharp edges and flat bars when you look at the wear pattern on the skirts. The majority of the pressure has been along the edges of the bars – and around where the screws were poking through them…

It is always fun to see how different makers built their trees. In this case, there is almost no change in the angle from the front of the bars to the back of where the stirrup groove would have been if these hadn’t been Arizona bars.

Then there was a lot of twist in a short distance, and minimal change behind there as well. Interesting…

And, typical of most production trees, the bars were very narrow.

So, Rod duplicated the tree, making the bars as much wider as he could while still making sure they will work in the old skirts. The wider bars will give more surface area to distribute the pressure better and he put our own rock, twist and crown shapes on them, so they will fit the horses better.

In the end, the customer will end up with a better saddle than he started with - but it will cost him to get it. This is just another example that the price tag on the saddle doesn’t guarantee the quality of the foundation in that saddle. Honestly, if most people knew the quality of what they were riding, they would spend the extra money for a good, hand made tree. (But maybe we are a bit biased…)