We are no longer building saddle trees, but we have two videos about how Western saddles fit horses available on our westernsaddlefit.com website.

Putting It All Together

|

|

| The fork and cantle have previously been temporarily attached to the bars with one screw on each corner. Now they need to be permanently attached to the bars. |

After checking that everything is still square, Titebond II glue is used between the pieces of the tree before reattaching cantle and fork to the bars. |

|

|

| Four or five holes, depending on the fork style, are drilled and countersunk on each side of the fork | and the fork is screwed on. |

|

|

| The cantle is attached in the same manner | with three screws each side. |

|

|

| Then the hole for the cantle thong is drilled at the front corner of the cantle. | A gouge is used to make a slot on the bottom of the bar for the end of the cantle thong to attach in. |

|

|

| The seat blend is completed by sanding with a sanding disc now that the cantle is permanently attached. | And other finishing touches are done. |

|

|

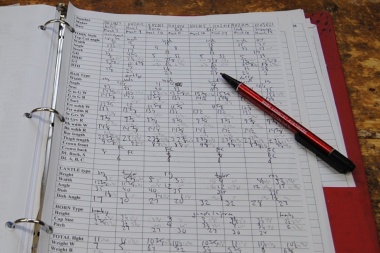

| Many measurements, both common and uncommon, are taken |

and recorded. The tree is again measured in the rawhide once it is dry. |

|

|

| Auto body filler is used to fill the screw holes | and around metal horns. |

|

|

| It is smoothed via rasp | or sanding disc. |

|

|

| Finally, three coats of marine varnish are applied | and the tree is ready for rawhiding. |