We are no longer building saddle trees, but we have two videos about how Western saddles fit horses available on our westernsaddlefit.com website.

Measuring a Saddle Tree

Introduction

“All tree makers do things differently” - including how they measure their trees. This page was written to describe what measurements we use, how we measure them and to clarify our terminology so we can communicate better when you place an order. All our measurements are with the rawhide on except the hand hole width and the stock thickness which we measure in the wood. When we make a tree, we allow for almost 1/8” of rawhide so that, for example, the width of the fork is about ¼” narrower and the seat length is about ¼” longer in the wood than we expect them to be when covered with rawhide. Since not all rawhide is equal thickness, there can be a bit of variation in final measurements, but it is generally within 1/8”.

Seat length

If people only know one measurement on a saddle, it is most likely seat length, yet the seat length measurement does not consistently measure the room in the saddle for the rider. It is affected by a number of variables which we explain in our Seat Length and Thigh Length Relationships page. We measure seat length from the top of the hand hole to the top of the cantle. Others measure from the base of the horn to the top of the cantle. We prefer the top of the hand hole because it is a consistent measuring point that is easy to find. A horn should blend smoothly into the fork making the actual point of the base of the horn very difficult to impossible find accurately, especially once covered. Saddle buyers need to know that a measurement taken on a finished saddle will be shorter than one taken on the tree by the thickness of the leather.

If people only know one measurement on a saddle, it is most likely seat length, yet the seat length measurement does not consistently measure the room in the saddle for the rider. It is affected by a number of variables which we explain in our Seat Length and Thigh Length Relationships page. We measure seat length from the top of the hand hole to the top of the cantle. Others measure from the base of the horn to the top of the cantle. We prefer the top of the hand hole because it is a consistent measuring point that is easy to find. A horn should blend smoothly into the fork making the actual point of the base of the horn very difficult to impossible find accurately, especially once covered. Saddle buyers need to know that a measurement taken on a finished saddle will be shorter than one taken on the tree by the thickness of the leather.

Thigh length

Another measurement that is more consistent in determining room in the saddle for the rider is the thigh length, measured from the forward most point on the cantle horizontally forward to the row of nails behind the fork. Most adults fit between 8 and 10 inches thigh length, though some people are bigger or smaller than this or want more or less room depending how tight or loose they like to be in the saddle, the style of fork they order, or the type of riding they plan to do. We know the correlation between seat length and thigh length for all the various combinations of fork and cantle specs on our trees, so we can tell you what the thigh length will be with the specs you have ordered. You can order by thigh length instead of seat length if you wish.

Another measurement that is more consistent in determining room in the saddle for the rider is the thigh length, measured from the forward most point on the cantle horizontally forward to the row of nails behind the fork. Most adults fit between 8 and 10 inches thigh length, though some people are bigger or smaller than this or want more or less room depending how tight or loose they like to be in the saddle, the style of fork they order, or the type of riding they plan to do. We know the correlation between seat length and thigh length for all the various combinations of fork and cantle specs on our trees, so we can tell you what the thigh length will be with the specs you have ordered. You can order by thigh length instead of seat length if you wish.

Note that thigh length cannot be measured in the same way on a finished saddle since with the rigging, jockeys and seat in place, you are actually measuring much higher up the on the cantle and the fork than with a bare tree. Because they lean away from each other, a measurement taken on a finished saddle will be longer than one taken on a tree. Also, the measuring point at the back of the fork is hidden under the seat, so you are guessing at where that place is.

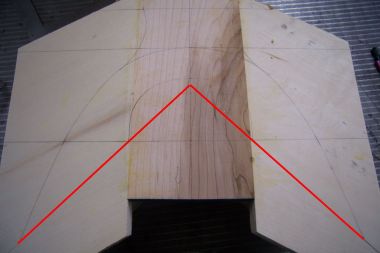

Bar angle

The terminology for the angle of the bars comes from the angle marked on the back of the fork prior to cutting anything out. As we explain on the Bar Angles: Why the Numbers are Meaningless Between Makers page, this angle cannot be measured on a finished tree, and even if you could measure it, different makers would still have different fits with the same angle. So you have to get to know how your tree maker’s specs fit on different horse types. Our 90 degree bar angle works well on in shape working horses with good withers. We use 93 degree for rounder backed horses or those with more muscle in the “wither pocket” area. A 95 degree bar works well on horses with really muscular withers and we have even made a few at 98 degrees for horses that are just flat and round, and a very few at 87 degrees for some super narrow withered horses.

The terminology for the angle of the bars comes from the angle marked on the back of the fork prior to cutting anything out. As we explain on the Bar Angles: Why the Numbers are Meaningless Between Makers page, this angle cannot be measured on a finished tree, and even if you could measure it, different makers would still have different fits with the same angle. So you have to get to know how your tree maker’s specs fit on different horse types. Our 90 degree bar angle works well on in shape working horses with good withers. We use 93 degree for rounder backed horses or those with more muscle in the “wither pocket” area. A 95 degree bar works well on horses with really muscular withers and we have even made a few at 98 degrees for horses that are just flat and round, and a very few at 87 degrees for some super narrow withered horses.

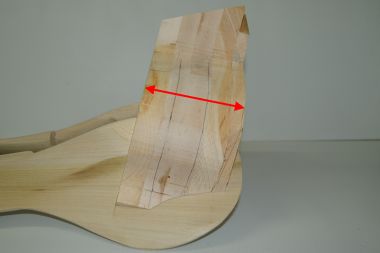

Hand hole width

We set the distance between the bars by the hand hole width measured at the point where the fork meets the bars. We don’t use the gullet width measurement at all. The Why We Use Hand Hole Width Instead of Gullet Width page explains this. Our hand hole measurements are in the wood. Some other makers use the measurement in the rawhide. This is an important distinction to have clear with your tree maker. Three and three quarter inches best fits narrower bodied horses, especially thoroughbred types. Four inches is a very common width for working ranch horses. Four and a quarter inches fits larger, wider horses. We will make the hand hole four and a half inches wide for exceptionally wide horses.

We set the distance between the bars by the hand hole width measured at the point where the fork meets the bars. We don’t use the gullet width measurement at all. The Why We Use Hand Hole Width Instead of Gullet Width page explains this. Our hand hole measurements are in the wood. Some other makers use the measurement in the rawhide. This is an important distinction to have clear with your tree maker. Three and three quarter inches best fits narrower bodied horses, especially thoroughbred types. Four inches is a very common width for working ranch horses. Four and a quarter inches fits larger, wider horses. We will make the hand hole four and a half inches wide for exceptionally wide horses.

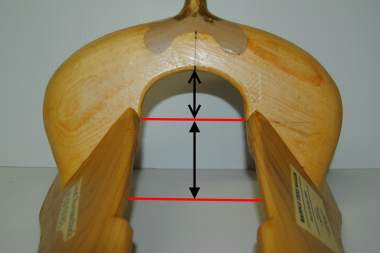

Gullet height and hand hole height

Gullet height is measured from a flat surface to the lip of the gullet. Hand hole height is measured from a flat surface to the top of the hand hole. How the two relate to each other is explained in the Avoiding the Withers - Using Hand Hole Height and Gullet Height Measurements page. For some fork styles, the look of the fork is what sets the gullet height, but generally gullet height is determined for reasons of fit – the gullet needs to clear the withers. Since contact can be made at the gullet lip, the hand hole or any place in between, both measurements need to be considered.

|

|

There are two components to both measurements – the bar component and the fork component. The bar component is a combination of the specs for the bars (set by the fit for the horse) and the bar depth. The fork component is set by the arch on the back of the fork. This is what we change to set hand hole and gullet heights. Both gullet and hand hole height measurements disappear when you lift the tree off the table, but the arch stays. How much clearance there is with the same height of arch will depend on the horse’s conformation and how well the bar specs have been chosen to match it. A hand hole height of 6 ¼” is pretty much a minimum for a horse with any kind of withers, though for some mutton withered horses 6” (or even lower) is still OK. Six and three quarter inches will clear just about everything if bar width and angle are chosen correctly. The gullet height becomes more of a concern if you have a tree with a thicker stock. You can order by either gullet height or hand hole height and we can help you in correlating the two if you need.

There are two components to both measurements – the bar component and the fork component. The bar component is a combination of the specs for the bars (set by the fit for the horse) and the bar depth. The fork component is set by the arch on the back of the fork. This is what we change to set hand hole and gullet heights. Both gullet and hand hole height measurements disappear when you lift the tree off the table, but the arch stays. How much clearance there is with the same height of arch will depend on the horse’s conformation and how well the bar specs have been chosen to match it. A hand hole height of 6 ¼” is pretty much a minimum for a horse with any kind of withers, though for some mutton withered horses 6” (or even lower) is still OK. Six and three quarter inches will clear just about everything if bar width and angle are chosen correctly. The gullet height becomes more of a concern if you have a tree with a thicker stock. You can order by either gullet height or hand hole height and we can help you in correlating the two if you need.

Fork width

The fork width is measured across the widest point on a swell fork. Twelve to fourteen inches is usual, though we have made them wider and narrower.

The fork width is measured across the widest point on a swell fork. Twelve to fourteen inches is usual, though we have made them wider and narrower.

There is no point at which to measure the width of a slick fork. An 8” is as slick as we generally make them, and a 10” is as wide as you can get without making the swell wider than the bottom of the fork. Nine inch is in the middle, and we generally change by ½” increments. We try to keep the middle of the fork as consistent as possible, but the shape does vary a bit depending on gullet height and bar specs. Please check out the Slick Forks and Wades pages to see pictures of different tree widths.

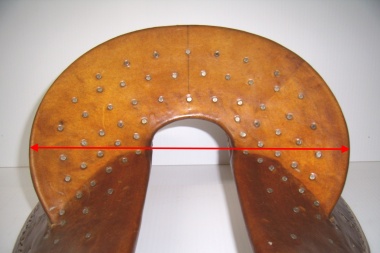

Stock thickness

The stock thickness is the thickness of the block of wood we start with before any shaping is done, so it will measure thicker in the rawhide. This can be difficult to measure on a finished tree because of the shaping and the angle of the fork, but we set it very accurately with the planer before we start shaping. We make swell forks and Weatherlys at 3 ¾”, 3Bs at 4 ¼”, Taylors at 4 ½” and Wades at 5” stock thickness unless you specify differently. If we put a wood post horn on a swell fork, we increase the stock thickness to 4 ¼” to balance the look of the larger horn unless requested otherwise. If you want a specific stock thickness, just let us know.

|

|

Horn height

Horn height is measured from the top of the fork to the front of the horn cap. We can set the height on wood post horns pretty exactly. In our opinion, wood post horns over 3 ¼” tall are harder to make look balanced unless they have bigger cap sizes, but we will make what the customer orders.

Horn height is measured from the top of the fork to the front of the horn cap. We can set the height on wood post horns pretty exactly. In our opinion, wood post horns over 3 ¼” tall are harder to make look balanced unless they have bigger cap sizes, but we will make what the customer orders.

On metal horn forks, the neck length and pitch of the horn is set when the horn is cast. Different cap sizes will cause the horn height to measure differently even when using the same horn. We try to get the horn to measure as close to the height you want given the horn type and cap size ordered. Horn height ranges from 2 ½” to 4” high are on hand. Please see The Basics on Horns page for more information.

Horn cap size

Horn cap size is measured across the diameter of the horn. Minimum size for a wood post horn cap is 3 ¼”. This is because we have set the narrowest size of the wooden neck at 2 1/8” in the wood (2 3/8” rawhided) for reasons of strength. Therefore to have any type of a lip, the minimum size of the cap is 3” in the wood which makes 3 ¼”once rawhided. We have made wood post horns up to 6” in diameter. The smallest cap size we have made on a metal horn is 1 ½” (1 ¼” in the wood). This doesn’t give much lip past the neck of the horn. The finished cap on a saddle will measure about ¾ to 1 inch larger than the cap size measured on the tree.

Horn Pitch

Wooden horns also come in different pitches. We label the pitches by the degrees we set on the band saw, but they are impossible to measure on a finished tree. The higher the pitch, the steeper the horn.

Wooden horns also come in different pitches. We label the pitches by the degrees we set on the band saw, but they are impossible to measure on a finished tree. The higher the pitch, the steeper the horn.

The pitch of a metal horn is set when it is cast. Most have a bit of pitch to them. Some have a more level cap. We set metal horns to follow the slope of the back of the fork unless requested otherwise. Changing the slope of the horn relative to the fork affects the look of the pitch of the horn.

The angle of the fork, leaned ahead or stood up, will also change the way the pitch of the horn will look on the horse. Our Metal Horns page and series of pages on Wood Post Horns have more explanation and lots of pictures.

Dome on the horn

We dome all horns appropriate to the cap size unless you request that it be flat.

We dome all horns appropriate to the cap size unless you request that it be flat.

Cantle Width

The cantle width is measured across the widest part of the cantle, with 11” to 13” being the usual range.

The cantle width is measured across the widest part of the cantle, with 11” to 13” being the usual range.

Cantle height

Cantle height is measured by putting a straight edge across the bars behind the cantle and measuring to the top of the center of the cantle. Most cantles are 3 ½” to 5” tall, though we do get the odd order for a 3” cantle, or an extra tall cantle.

Dish

Dish is measured by putting a straight edge across the cantle and measuring between the ruler and the top of the cantle gullet, which is the deepest part of the seat. 1 ½” dish is about the maximum. 1 ¼” is the most common order we get. Depending on the style of cantle, 1” is not an uncommon measurement and we get some orders for less than 1” as well.

Cantle Angle

The angles we use to describe our cantles come from the angles on the jigs we use when we cut them out and are impossible to measure on a finished tree. The smaller the angle, the more laid back. The larger the angle, the more stood up. The best angle to choose for a specific tree depends on the height of the cantle as well as the maker’s preference. Generally, the shorter the cantle, the more laid back it needs to be. The taller cantles should be more stood up.

The angles we use to describe our cantles come from the angles on the jigs we use when we cut them out and are impossible to measure on a finished tree. The smaller the angle, the more laid back. The larger the angle, the more stood up. The best angle to choose for a specific tree depends on the height of the cantle as well as the maker’s preference. Generally, the shorter the cantle, the more laid back it needs to be. The taller cantles should be more stood up.

For further information on cantles – shape, the three different slopes you see, Taylor versus Regular cantles and how the height and width affect the angle and dish you choose, please see our Cantle Conundrums page.