We are no longer building saddle trees, but we have two videos about how Western saddles fit horses available on our westernsaddlefit.com website.

Cantle Conundrums

Cantles are complicated

There is a lot more that goes into the look of a cantle than the shape of its outline, and making a cantle that fits squarely onto the bars is a mathematical nightmare (which is why we didn’t figure it out mathematically!). On this page we try to explain some of the factors that affect how a cantle will look and to do that we need to explain a bit of how we make them. Understanding the variations in the factors involved will help you get more of the look you want and make it easier to build your groundseat because the cantle will already be shaped the way you want. Here is our best attempt to make it all as plain as we can.

Three Slopes Of a Cantle

When you look at a cantle from the side, there are three different angles or slopes that you see:

A.) the angle of the rim of the cantle (the cantle angle)

B.) the slope of the face of the cantle and

C.) the slope of the back of the cantle. In the way we build trees the first has a set measurement that determines it even though it is not measurable on a finished cantle. The other two slopes are a result of the combination of dish, height, width, structural considerations and personal preference.

|

|

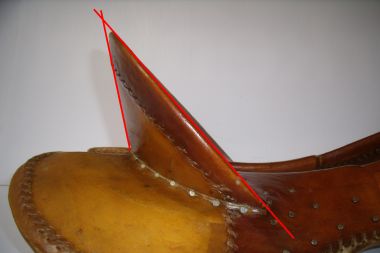

| Back slope and cantle angle | Slope of face of cantle |

A.) Cantle Angle

We have described how we laminate our cantles in our Construction Materials page. Essentially, we take the block of wood glued up for a cantle, set it on the bars and tip it back a bit. When all is said and done, the rim of the cantle is all that is left of the front of that piece of wood and the angle of that rim relative to the bars is what we call the cantle angle. You can still see how far back the cantle is tilted on a finished tree if you look at the cantle directly from the side. Note: not all tree makers keep that rim flat so in looking at their cantles from the side, there is not one cantle angle but curves or a broken back angle. However, changing the angle that is cut on bar surface of the cantle will change the orientation of these cantles relative to the tree in the same way as described below.

|

|

Our Terminology for Cantle Angle

The numbers we use to describe the cantle angle (32.5, 35, 37.5, 40, 42.5 or 45 degree) are taken from the jigs we use to cut the bottom of the cantles so they still fit on the bars correctly even though they lean at different angles. This is one of the first steps in making the cantle. Even though the difference may be difficult to see in the pictures, it is visible in real life and does make a difference in overall look to the cantle.

|

|

|

| 4 1/2" high cantle at 35 degrees | 4 1/2" high cantle at 37.5 degrees | 4 1/2" high cantle at 40 degrees |

|

| 5 1/2" tall cantle at 42.5 degrees |

You cannot measure that actual angle - not from the table, not from the bars, and not even on the cantle itself once it is finished being shaped prior to attaching it to the tree. There are other angles involved so that even if other makers use the same numbers as we do, their cantles may lean at different angles than ours on the finished tree, therefore please don’t use these numbers to try to compare between makers. We could call them Regular (37.5 degree), Laid Back (35 degree) and Stood Up (40 degree). But since these terms can mean different things to different people, we have decided call them by the jig angle just to be clear in communicating with you. Once you get a tree and see what it is like, you can decide if you want a different cantle angle the next time. By the way, we can also do angles at 42.5 degrees (Even More Stood Up) and 45 degrees (Really, Really Stood Up) for those who want that extreme look or for extra tall cantles, and 32.5 (Even More Laid Back) for the shorter cantles.

Deciding on Cantle Angle

The height of the cantle really affects which cantle angle you choose. First off, there is the look of the finished cantle. The shorter the cantle, the less difference there is in look between the different angles. The taller the cantle, the more distance the eye has to travel to get to the top, so the 35 degree cantle looks comparatively more laid back while the 40 degree cantle looks comparatively more stood up. We don't make 5" tall 35 degree cantles just because they lean way too far back for that height. Secondly, there are structural problems when you try to stand up shorter cantles so they are best at the more laid back 35 degree angle. More explanation on that later. We can help you in figuring this out on your early orders if you want.

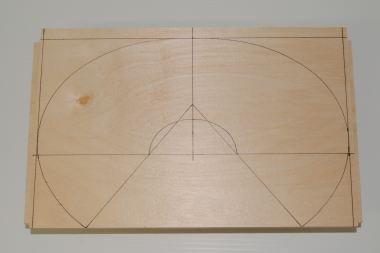

Setting up the Cantle Outline Shape

Once the cantle angle has been decided, the shape or outline of the cantle is marked out. It has to fit inside a box. The height of the box is determined by the height of the cantle, the angle of the cantle and whether the cantle is a regular or a Taylor. The width of the box is determined by the width of the cantle. Inside that box, we can draw whatever shape we want, so long as our line touches the top and sides, and starts and ends at two specific points at the bottom of the box. These points are the front corners or points of the cantle. Even these may be adjusted a little bit, but changing this changes all sorts of other measurements on the tree. We try to make our cantles as round as possible given the dimensions of the box unless asked otherwise. You will notice that, as for the layout of a fork, we draw a vertical and a horizontal line as starting points in setting up the cantle pattern. The horizontal line marks where the bottom of the cantle gullet meets the inside edge of the bars. How high that horizontal line is compared to the points of the cantle as well as the angle we use varies depending if it is a regular or a Taylor cantle. Changing these alters the look of the cantle even if the box is the same total height and width. Of course, these measurements and angles are different for every tree maker. The cantle outline is then cut out.

Once the cantle angle has been decided, the shape or outline of the cantle is marked out. It has to fit inside a box. The height of the box is determined by the height of the cantle, the angle of the cantle and whether the cantle is a regular or a Taylor. The width of the box is determined by the width of the cantle. Inside that box, we can draw whatever shape we want, so long as our line touches the top and sides, and starts and ends at two specific points at the bottom of the box. These points are the front corners or points of the cantle. Even these may be adjusted a little bit, but changing this changes all sorts of other measurements on the tree. We try to make our cantles as round as possible given the dimensions of the box unless asked otherwise. You will notice that, as for the layout of a fork, we draw a vertical and a horizontal line as starting points in setting up the cantle pattern. The horizontal line marks where the bottom of the cantle gullet meets the inside edge of the bars. How high that horizontal line is compared to the points of the cantle as well as the angle we use varies depending if it is a regular or a Taylor cantle. Changing these alters the look of the cantle even if the box is the same total height and width. Of course, these measurements and angles are different for every tree maker. The cantle outline is then cut out.

Special Cantle Shapes

Special shapes may be accommodated, so long as they fit inside and touch the edges of the box. Spade shaped cantles are the most common special request, but we have had makers who want something just a bit different. In this case, we have made up templates for them (i.e. we have drawn out the box for the specs they want) so they could draw in their own shape and send back to us to use as a pattern.

|

|

|

| Wider spade shaped cantle | Narrow spade shaped cantle | Special customer drawn shape |

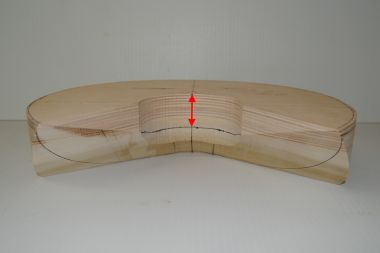

Dish

The next thing to do is work on the dish. As explained in our Measuring a Saddle Tree page, the final dish is measured by putting a straight edge across the cantle and measuring from it in to the deepest part of the seat, the top of the cantle gullet. To make the dish, we measure in from the face of the cantle the appropriate distance and make a line inside the cantle gullet at that distance. The cantle is dished out to that line. It is also carved down to a sharp edge where the dish meets the underside of the cantle. This edge fits under the cantle cut on the bar. (Please see the Building a Cantle page in our Building a Saddle Tree section for pictures.)

|

|

B.) The Slope of the Face of the Cantle

This changes with a number of factors, the most important of which are the amount of dish, the cantle angle and the height of the cantle. Beveling the edge also affects it somewhat, particularly if the bevel is wide. Cantle width doesn’t affect the slope up the center of the face, but it does affect the change in slant from the edges to the center. We have figured out how to compare this slope between our own trees by measuring from the table up the face of the cantle. However, this is one of those “Do not try this at home” situations. Any variation in bar shapes, angle, etc. will affect this measurement so it is useless to compare between makers and even between some variations within one maker’s trees. Over time we have figured this out on our trees so we can give you a relative comparison of the slopes with the different variables discussed below. If you are interested in how this affects your orders, please ask us.

This changes with a number of factors, the most important of which are the amount of dish, the cantle angle and the height of the cantle. Beveling the edge also affects it somewhat, particularly if the bevel is wide. Cantle width doesn’t affect the slope up the center of the face, but it does affect the change in slant from the edges to the center. We have figured out how to compare this slope between our own trees by measuring from the table up the face of the cantle. However, this is one of those “Do not try this at home” situations. Any variation in bar shapes, angle, etc. will affect this measurement so it is useless to compare between makers and even between some variations within one maker’s trees. Over time we have figured this out on our trees so we can give you a relative comparison of the slopes with the different variables discussed below. If you are interested in how this affects your orders, please ask us.

1.) Affected by Dish

The dish, along with the height and angle of the cantle, is what determines how steep the face of the cantle ends up. The more dish you order, the further back the top of the cantle gullet is compared to the outside rim of the cantle. Ordering a cantle with a lot of dish (solid line) effectively "straightens" the face of the cantle into a more upright position than if you had ordered less dish (dashed line). It also makes a deeper cup relative to the sides of the cantle.

2.) Affected by Cantle Angle

Three cantles with the same height, width, and dish but with three different cantle angles, would look pretty much the same if you held them in your hand before they were attached to the tree because the measured dish has to do with the center of the cantle relative to the rim of the cantle. However, once you put those three cantles onto identical bars, the steepness of the face of the cantle relative to the bars is different, because the angle of the cantles relative to the bars is different. The more laid back cantle angle (red line) would have a more gradual slope to the face of the cantle (dotted red line), while the more stood up cantle angle (black line) would have a steeper face (dotted black line). You can achieve the same slope to the face of the cantle by ordering a steeper cantle with less dish, or a laid back cantle with more dish. Cantle angle affects, but does not determine, steepness of the slope of the face of the cantle. They are independent.

Three cantles with the same height, width, and dish but with three different cantle angles, would look pretty much the same if you held them in your hand before they were attached to the tree because the measured dish has to do with the center of the cantle relative to the rim of the cantle. However, once you put those three cantles onto identical bars, the steepness of the face of the cantle relative to the bars is different, because the angle of the cantles relative to the bars is different. The more laid back cantle angle (red line) would have a more gradual slope to the face of the cantle (dotted red line), while the more stood up cantle angle (black line) would have a steeper face (dotted black line). You can achieve the same slope to the face of the cantle by ordering a steeper cantle with less dish, or a laid back cantle with more dish. Cantle angle affects, but does not determine, steepness of the slope of the face of the cantle. They are independent.

3.) Affected by Cantle Height

The shorter the cantle, the less distance there is between the top of the cantle and the top of the cantle gullet, so if you order the same amount of dish, the same depth of wood still has to be removed in this shorter distance. The result is that for the same cantle angle and dish, if you lower the height, you make the slope of the face of the cantle steeper. As you raise the height, the slope of the face becomes more laid back. Therefore, you can get the same slope of the face of the cantle with a short cantle and less dish as you can with a tall cantle and more dish. The practical result is that on short cantles (3 and 3 1/2" tall), to get 1 1/4" dish means that the face of the cantle is very steep, even with a 35 degree cantle angle. If a 40 degree cantle was ordered at 3" high with 1 1/4" dish, the face of the cantle would be going backwards.

|

|

| 3" tall cantle at 35 degrees with 1 1/4" dish | 4 1/2" tall cantle at 35 degrees with 1 1/4" dish |

4.) Affected by a Wide Bevel

Ordering a bevel cantle may also make you reconsider the amount of dish you want. The dish is then removed starting, not from the rim, but from the inside of the bevel, which is on the same plane as the rim would be on a non-beveled cantle. This has the same effect as making the cantle shorter and narrower. Most wide bevel cantles we do are on 40 degree cantles. So the effect on the dish of ordering a bevel is to effectively order a shorter, narrower cantle that is relatively stood up, all of which make the slope of the face of the cantle steeper. You may want to consider ordering less dish on these cantles.

Dish and Cantle Width Effects

The width of the cantle has the same type of effect from the side to the center as the height does from top to the center. The narrower the cantle, the deeper the "cup" gets from side to side. You don't get the same amount of effect that changing cantle height gives because the cantles are wider than they are tall, so in most cases changing dish based on cantle width isn’t warranted. However, really narrow cantles may benefit from having less dish.

C.) Back Slope

The last major thing before the cantle is finished is to cut off the back of the cantle and sand it down to its final shape. (Pictures available on our Building a Cantle page.) The slope of the back can be varied independently of the cantle angle and the dish. Making the back of the cantle slope more forward from top to bottom makes the cantle appear more laid back regardless of the cantle angle and slope of the face. It also makes the wood at the bottom thinner, so there are structural considerations here. Making the back more vertical makes the cantle appear more stood up, and also gives you more wood at the cantle base. Some people like the look more sloped, and some like it more vertical.

The last major thing before the cantle is finished is to cut off the back of the cantle and sand it down to its final shape. (Pictures available on our Building a Cantle page.) The slope of the back can be varied independently of the cantle angle and the dish. Making the back of the cantle slope more forward from top to bottom makes the cantle appear more laid back regardless of the cantle angle and slope of the face. It also makes the wood at the bottom thinner, so there are structural considerations here. Making the back more vertical makes the cantle appear more stood up, and also gives you more wood at the cantle base. Some people like the look more sloped, and some like it more vertical.

Cantle Thickness: the Limiting Factor

While there is no limit to how thick the wood at the cantle gullet can be, we do have a minimum thickness of wood that we like to keep for strength. This will limit how much back slope there can be on some cantles. Ordering a lot of dish takes more wood from the front of the cantle, so the back needs to be further back to keep the same thickness of wood. As the cantle gets taller and its top moves further away from the top of the cantle gullet, it also moves further back, leaving more thickness available at the bottom. This means you can have more back slope on a taller cantle than a shorter one and still keep the minimum wood thickness. The top of a more laid back cantle moves further back from the fork than a more stood up one at the same height, so a more laid back cantle can have more back slope and still be thick enough at the bottom. A Taylor cantle can have more back slope than a regular. There are no set angles to the back slope. If you want to be more specific, asking for the cantle back to be vertical when on a horse or more sloped are options. We will do what we can within the above limitations.

|

|

Short Cantles and Back Slope

Short cantles are the ones that tend to cause problems with back slope. There is not much distance from the top of the cantle gullet to the top of the cantle, so the wood that is there needs some thickness to it to be strong enough. To keep the minimum wood thickness, the back often needs to be vertical or, in a few cases, even slope towards the back a bit. This is not the most aesthetically pleasing so it is good that most really short cantles have a Cheyenne roll and the back of the cantle is not seen much anyway.

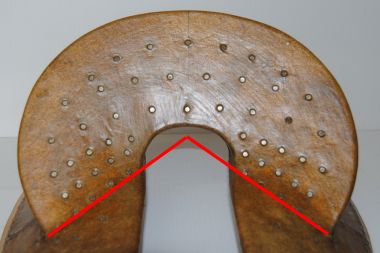

Taylor versus Regular Cantles

1.) What’s the difference?

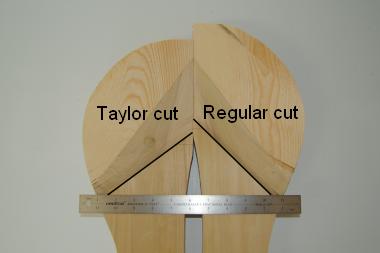

Even with the same width, height and angle, the cantle will look different depending if it is a Taylor or a Regular. The primary change is the change in angle of the cantle cuts on the bars and, correspondingly, the change in angle on the cantle to make it fit into the cantle cuts. When you look from the front of the tree towards the cantle, you will see this angle by looking at the row of nails going from the front corner towards the bottom of the cantle gullet where the cantle and the bar meet. The angle is flatter on a Taylor cantle than on a regular. A second major difference is that the horizontal line across the bottom of the cantle gullet is closer to the cantle points on a Taylor. This makes them look taller, as there is comparatively more cantle above the horizontal line for the same height cantle. A lot of the old high backed saddles have tall cantles with minimal dish and these look very similar to our taller Taylor cantles. Please note that all the angles used on cantles and bars vary substantially between makers. Regular and Taylor is the terminology we were given when we started to build trees and we have kept it, but this terminology is not consistent between makers either.

|

|

| More acute angle Regular cantle - 4 1/2" high x 12" wide at 40 degrees |

Flatter angle Taylor cantle - 4 1/2" high x 12" wide at 40 degrees |

2.) Why have two types?

Because there are limits to how much and how little dish there can be in a cantle with only one angle here. To have an inch or less of dish (depending on the cantle angle) with a regular cantle is not possible because the angle described above is too narrow. So to get less dish, we make a Taylor. What essentially happens is that the corners stay the same but the cantle gullet moves forward, making less dish an option. Why not just make Taylor cantles? Because you can’t get more than an inch of dish with that angle. So we need the two.

3.) Seat length, thigh length and bar length in relation to cantle types

All the changes that are made when changing from a regular to a Taylor cantle leave thigh length relative to seat length almost the same. But changing to a Taylor cantle results in shorter bars relative to seat length. This is because the point at which the cantle gullet meets the inside edge of the bars is the starting point we use when determining how far back the bar goes behind the cantle. If you move this point forward by changing the cantle cut angle on the bars, the bars are shortened by a similar amount. On our trees, this is close to an inch.

I have written a blog post with more pictures to compare between the two types of cantles.

Bevels

Bevels are ordered for a couple of different reasons. Some are ordered to achieve a certain look to the finished cantle. Some smaller bevels are ordered to make it easier to lay the cantle binding back from the edge. This is more of a concern on cantles that are more stood up. You can order a specific width of bevel both from the edge of the rim down, and the edge of the rim back. We have had them ordered from 3/8" to 1 1/4" deep. 1/8" back is usual for smaller bevels, but you can go up to 1/4" back with a deeper bevel.

|

|

| Wider bevel - 3/4" by 3/16" | Narrower bevel - 3/8" x 1/16" |

Bevel Cantles and Seat Length Measurements

Something to keep in mind is that when making a bevel cantle, we make the cantle to the correct seat length and then do the bevel. This means that the edge of the cantle is a little bit further back than the ordered seat length, and the angle of the bevel is a little bit further ahead than the ordered seat length. The bevel also lengthens your measured thigh length slightly though it doesn’t change the cantle gullet to fork gullet measurement at all. If you need something very specific, discussing it in detail with us will help in us trying to achieve what you want.

Shovel Cantles

There are at least three different definitions of shovel cantle. One is a very upright, round cantle. One is a Taylor cantle. And one is a spade shaped cantle. We can make any of these cantles, but we need to know which type you want. That is why we will ask you to define specifically what you want if you ask for a “shovel cantle”.