We are no longer building saddle trees, but we have two videos about how Western saddles fit horses available on our westernsaddlefit.com website.

Bar Angles – Why the Numbers Are Meaningless Between Makers

Introduction

Different methods have been tried over the years to be able to compare the fit of trees between tree makers. One of the latest is talking about bar angles, the most common being 90 and 93 degrees. But how do you know the angle at which the tree maker sets the bars? A very common question to which the answer is – you can’t unless they tell you. Trying to measure a finished tree with an angle gauge anywhere to determine the “bar angle” is a futile endeavor. First, there is no place you can physically measure what we mark out. Second, the angle marked on the back of the fork does not make a consistent fit due to other angles in the tree. And third, the marking and shaping of the bars makes it all redundant anyway. Here is our explanation as to why.

Defining “Bar Angle”

Most hand made tree makers set their bar angle on the back of the fork when they mark it out. This is where the 90, 93 or other degrees get their name.

Why You Can’t Measure It

Attempting to measure this angle is futile is because this section disappears into the fork cuts and is inaccessible once the tree is together even before it has been rawhided. As you can see the angle on the fork differs from the fork cut on the bars it is set into.

|

|

Why Measuring It Wouldn’t Help Anyway

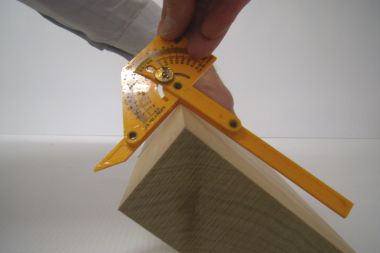

The bottom of the fork is cut out at an angle, getting wider towards the front This angle not only varies between makers, but is changed depending on how stood up or leaned ahead the fork will be. Why is that important? Because when you introduce that third angle, 90 degrees is no longer 90 degrees. As you can see in the pictures below, when the protractor is placed on a 90 degree corner, it matches the corner. But when you add in that pesky third dimension by tilting the protractor, you can see the space developing between the ends of the square and the wood. The further it is leaned, the greater the space.

The bottom of the fork is cut out at an angle, getting wider towards the front This angle not only varies between makers, but is changed depending on how stood up or leaned ahead the fork will be. Why is that important? Because when you introduce that third angle, 90 degrees is no longer 90 degrees. As you can see in the pictures below, when the protractor is placed on a 90 degree corner, it matches the corner. But when you add in that pesky third dimension by tilting the protractor, you can see the space developing between the ends of the square and the wood. The further it is leaned, the greater the space.

|

|

This means that when a fork is tilted, it effectively changes the angle, and the more a fork is leaned ahead, the wider the resultant angle actually gets. A tree with a fork marked out at 90 degrees and leaned ahead will measure wider across the bottom of the bars than the same fork with the same bar type and same hand hole width, but stood up. This is one of the reasons why what is marked on the back of the fork is not what people sometimes try to measure on the top of the front of the bars ahead of the the fork. We compensate for fork angle differences by changing the angle we mark on the back of the fork so that all our “90 degree” trees fit the same. (We call it 90 degree equivalent.) Other makers may change it the same way or use different methods to achieve the same end, and some don’t compensate at all. So even if you could measure what we mark on the fork, what the actual measurement is may not be what we call the corresponding fit.

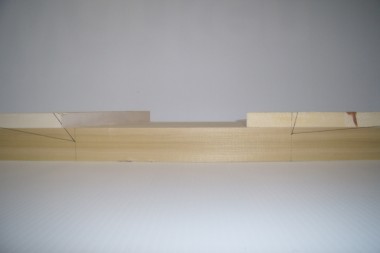

And Then There Are the Cuts On the Bars

The fork has to fit into cuts made on the bars, and those cuts are in three dimensions as well. The angles of the fork cuts on the bars are crucial to set the front of the bars, but they also work in conjunction with the angles on the fork to determine how far apart the back of the bars end up, which affects the angles there too. Getting the fork cut angles and cantle cut angles to work together is vital not only to fit the fork and cantle onto the bars properly, but to fit the horse as well. You will note that the angles cut on the front of the bars are different than those cut on the back of the bars.

|

|

| Back and front bar cuts marked out | Front bar cut seen from the inside of the bar |

|

|

| Front bar cut seen from the front | Back bar cut seen from the back |

Connections Aren’t the Whole Story

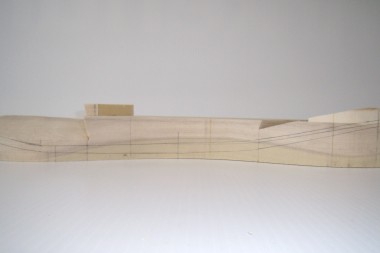

But those angles and numbers only apply to how the bars and the fork connect. The reference marks for shaping the bottom and the top of the bar are marked along the edge of the bars. These markings vary in distance from each other as you go along the length of the bar and are angled differently across the bar compared to each other as well. These markings are what set the twist and can also be used to influence the rock in the bar. For example, the inside of the front bar pad comes to a sharp edge, merging smoothly with the fork. On the outside, the top of the bar is rasped off, angling down from the fork cut. And every tree maker marks his bars out differently.

But those angles and numbers only apply to how the bars and the fork connect. The reference marks for shaping the bottom and the top of the bar are marked along the edge of the bars. These markings vary in distance from each other as you go along the length of the bar and are angled differently across the bar compared to each other as well. These markings are what set the twist and can also be used to influence the rock in the bar. For example, the inside of the front bar pad comes to a sharp edge, merging smoothly with the fork. On the outside, the top of the bar is rasped off, angling down from the fork cut. And every tree maker marks his bars out differently.

|

|

| Inside edge | Outside edge |

Fit Always Has To Do With Shape

What is really crucial is how the bars, particular the bottom of the bars, are shaped. They are rounded, but not evenly like half a sphere or half an oval. The curve varies from one edge to other and from one section of the bar to another. We use more than one crown pattern and, of course, these patterns vary from one tree maker to another.

Measuring Across the Bottom of the Bars

Some people try to compare by measuring across the bottom of the bars and comparing that with the hand hole measurements. And that would work if the depth (or width) of the bars themselves were the same. Once again, “every tree maker does things differently”. On our Wade bars, the difference in the measurement across the bottom of the front bar pads between 90 and 93 degrees, everything else being the same, is only 1/8”, while the difference between the same "fit" with regular versus Wade bars is up to half and inch. So you can see how inaccurate this method of comparing trees is with even a small difference in bar depth or shape. And while some makers are very similar to others, none that we have found are identical.

Some people try to compare by measuring across the bottom of the bars and comparing that with the hand hole measurements. And that would work if the depth (or width) of the bars themselves were the same. Once again, “every tree maker does things differently”. On our Wade bars, the difference in the measurement across the bottom of the front bar pads between 90 and 93 degrees, everything else being the same, is only 1/8”, while the difference between the same "fit" with regular versus Wade bars is up to half and inch. So you can see how inaccurate this method of comparing trees is with even a small difference in bar depth or shape. And while some makers are very similar to others, none that we have found are identical.

Geometry and Bar Angles

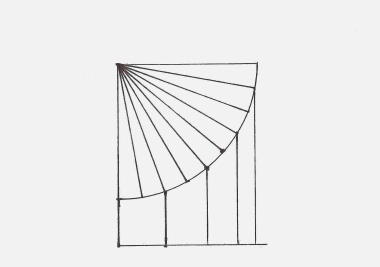

Another interesting aspect of geometry is that as you progressively increase the angle, every degree increase makes less and less comparative difference to the width across the bottom of the bars. (Thanks go to David A Morris, a saddle and tree maker in Australia, for showing this to us. It seems very obvious once you know it, but somehow we missed this lesson in geometry class.) You can see that for the first 20 degree spread from the vertical, the distance is greater than for the next 20 degree spread. This results in the difference in measurement across the bottom of the bars between 90 and 93 degrees being slightly greater than the difference between 93 and 96 degrees. So for some of these really wide horses, increasing the bar angle to what may seem to be a large amount is not making as much of a difference as we originally might have thought.

Another interesting aspect of geometry is that as you progressively increase the angle, every degree increase makes less and less comparative difference to the width across the bottom of the bars. (Thanks go to David A Morris, a saddle and tree maker in Australia, for showing this to us. It seems very obvious once you know it, but somehow we missed this lesson in geometry class.) You can see that for the first 20 degree spread from the vertical, the distance is greater than for the next 20 degree spread. This results in the difference in measurement across the bottom of the bars between 90 and 93 degrees being slightly greater than the difference between 93 and 96 degrees. So for some of these really wide horses, increasing the bar angle to what may seem to be a large amount is not making as much of a difference as we originally might have thought.

The Conclusion Is…

The numbers themselves are meaningless to determine how a tree will fit. A wider angle number tree will fit wider horses better than a narrower angle number tree within one maker’s trees, but between makers there is no guarantee the fit is similar at all. The tree makers whose patterns and methods come from the same “genealogy” will have trees that fit in a similar but not identical way. With different bar patterns and methods of building trees, the fit will be a lot less similar. This is why you have to talk with your tree maker, trust his judgment for the first one or two and then try them on a bunch of horses. That is the only way to learn what their “4 x 90” or “semi-quarter horse” or whatever term they use to describe their fit really means.