We are no longer building saddle trees, but we have two videos about how Western saddles fit horses available on our westernsaddlefit.com website.

Avoiding the Withers – Using Hand Hole Height and Gullet Height Measurements

Clearance – the reason behind the measurements

Clearance under the fork for the horse’s withers is vital because any sustained pressure on the top of the spinal processes of the vertebra can cause severe and long term, even deadly in the long term, damage. This contact can occur not just at the gullet lip but anywhere under the fork, right back to the hand hole. It is imperative that the saddle clears the spine all the way along the back as well. The traditional gullet height measurement is supposed to tell you how much clearance there will be for this tree in comparison to other trees. Since the withers often contact the gullet more towards the hand hole than at the gullet lip, both measurements need to be taken into consideration. However, gullet height and hand hole height do not change consistently with each other. Hand hole height can vary quite at bit between trees that have the same gullet height. Understanding the two components that go into both measurements along with the four factors that affect the correlation between the two will help you get the look you want and the clearance you need for the saddle you are building.

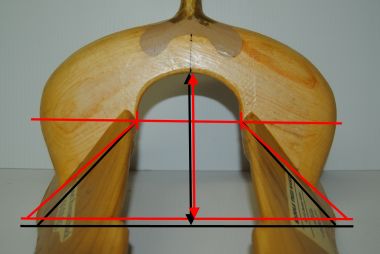

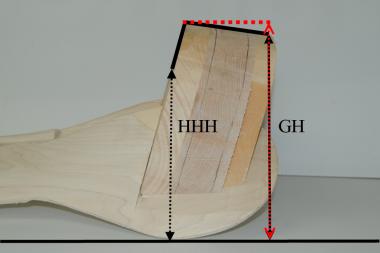

A) Measuring gullet and hand hole height

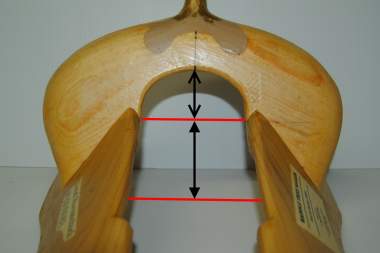

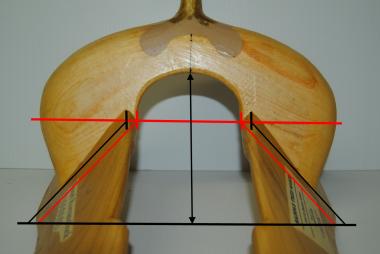

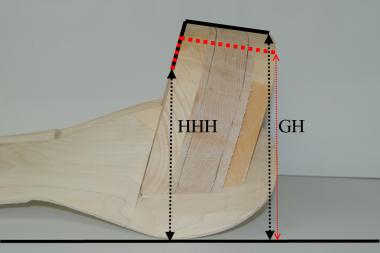

As we explain in our Measuring a Saddle Tree article, both gullet height and hand hole height are measured from a flat surface the tree is sitting on. Therefore, they can be considered “artificial measurements” since they disappear as soon as you pick up the tree.

|

|

B) Two components to gullet and hand hole height measurements

There are two components to both gullet height and hand hole height – the part contributed by the bars, and the part contributed by the fork. It is important to understand that these parts can be, and should be, changed independently of each other. Ideally, final gullet and hand hole heights are set by changing the fork component to clear whatever wither height is expected only after the bar specs are chosen to fit the horse properly.

There are two components to both gullet height and hand hole height – the part contributed by the bars, and the part contributed by the fork. It is important to understand that these parts can be, and should be, changed independently of each other. Ideally, final gullet and hand hole heights are set by changing the fork component to clear whatever wither height is expected only after the bar specs are chosen to fit the horse properly.

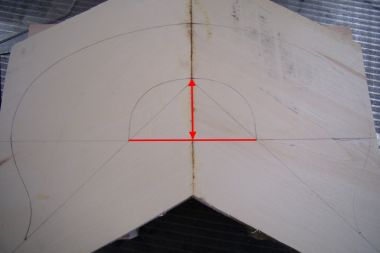

1) The fork component

The fork component is the arch we draw on the back of the fork before cutting it out. The bottom corner of the arch fits into the cuts made on the bars, and the height of the arch is what we vary to change hand hole and gullet height within the same bar specs. A 1” variation is all that is generally needed to accommodate different wither heights provided that the bar width and angle are chosen correctly to fit the horse’s body type.

|

|

2) The bar component

The bar component goes from where the bottom of the arch fits into the fork cuts on the bars down to the table. There are three primary factors about the bars which need to be considered when dealing with gullet and hand hole height: 1) bar depth, which affects the measurements but may not affect the fit, 2) bar width or spread, which affects the fit on the horse but not the measurements, and 3) bar angle, which affects both fit and measurements.

a) Bar depth

The bar depth, or width of the bar itself, affects how far the fork sits above the table but if the fit is the same, the fork will clear the withers by the same amount regardless of bar depth. We only have two outline patterns which we use, our Wade and our regular, and there is only ¼” difference in their width/depth. Because the Wade bars are deeper, they raise the gullet and hand hole relative to the table by approximately 1/8” compared to the same fork with regular bars. (Why not 1/4"? Because they are set an an angle, not perpendicular to the table.) However on a horse that the trees fit properly, the Wade bars will go down the side of the horse ¼” farther than the regular bars but the distance above the withers will be the same. Therefore, bar depth affects both measured gullet height and hand hole height, but not the clearance on the horse.

|

|

b) Bar spread or bar width

The bar spread, or width between the bars, has a major effect on the fit for the horse. (Please see Factors That Affect Tree Fit.) The wider the spread, the lower the tree will sit on the horse so the less clearance there will be under the gullet. If the tree is too wide, it will tilt forward on the horse, decreasing the clearance even more. However, increasing the hand hole width does not change either the hand hole or gullet height measurements. This is one of the reasons why it is so important to get the specs that affect bar fit correct before deciding on hand hole or gullet height.

c) Bar angle

Changing the bar angle affects the fit on the horse because the bars change their position relative to the horse’s back. (Please see Factors That Affect Tree Fit.) It also changes the hand hole and gullet height measurements. Widening the angle drops the fork relative to the table. Narrowing the angle moves the fork farther away from the table. On our trees, this means 1/16" to a maximum of 1/8” difference for each three degree change, depending on bar depth. The same effect occurs on the horse, but how the measurement difference compares to the clearance difference on the horse depends on the conformation of the horse and the fit of the overall tree.

Factors that affect the gullet height relative to the hand hole height

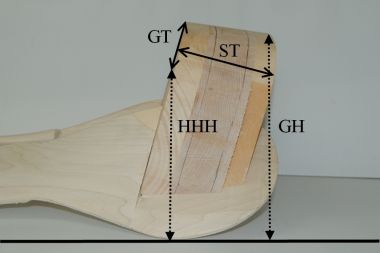

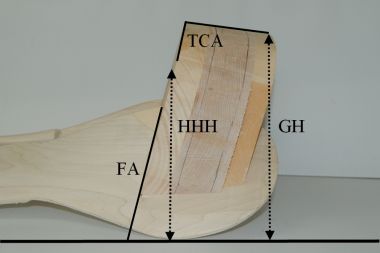

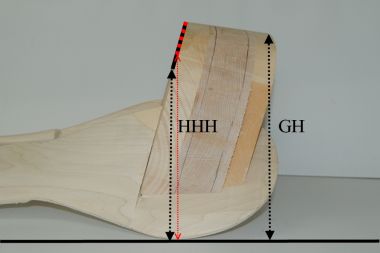

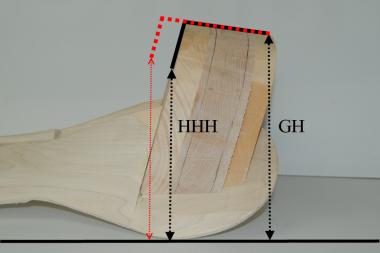

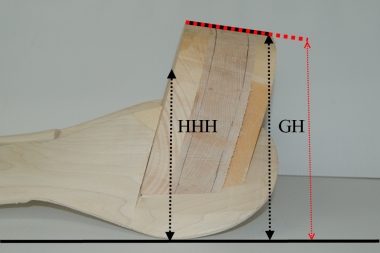

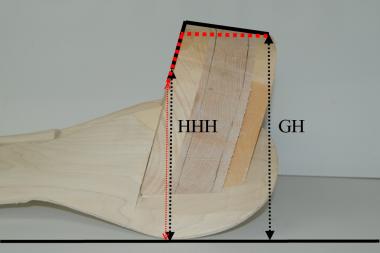

If all forks were built identically, the hand hold height and fork height would change the same amount as the height of the arch drawn on the back of the fork was changed. But there are four other factors that change the relative position of hand hole height (HHH) and gullet height (GH) – the gullet thickness (GT), the stock thickness (ST), the top cut angle (TCA) and the fork angle (FA).

|

|

| Stock thickness (ST) and gullet thickness (GT) demonstrated. | Top cut angle (TCA) and fork angle (FA) demonstrated. |

1) Gullet thickness

The thicker the wood between the top of the hand hole and the top of the fork, the higher the gullet will be, all else being the same. This doesn’t increase overall clearance since the hand hole stays the same, but the gullet will measure higher. This is why a wood post horn gullet can be so much lower than a metal horn gullet with the same hand hole height. The metal horn fork needs enough gullet thickness to take the screw length needed to hold the horn on. On our trees, we mark out the gullet to be 2 1/8” thick at the back. On a wood post horn fork with good quality wood and the horn built in as an integral part of the fork, you can cut that down substantially. We mark out the gullet thickness at 1 ¼” on our Wade trees. That is 7/8” difference in gullet height, and therefore base of horn height, relative to the horse’s withers with the same amount of clearance at the hand hole. This is one advantage to having a wood post horn when roping. We can decrease the gullet thickness the same amount on wood post swell forks but that often shortens the fork so much it distorts the shape of the swells. So while we do decrease gullet thickness on these compared to a similar fork with a metal horn, we don’t make it as thin as we do on a Wade, not for strength, but for appearance.

|

|

| With the same gullet height, the hand hole height increases with a thinner gullet and drops with a thicker gullet. | With the same hand hole height, the gullet height increases with a thicker gullet and decreases with a thinner gullet. |

2) Stock thickness

The stock thickness is the thickness of the fork measured front to back. Because most forks on western saddles lean ahead, the top of the fork usually angles down. Therefore, as the stock gets thicker, the lip of the fork gets lower, all else being the same. This is a consideration if you order a tree with really thick stock. You may want to raise the gullet height a bit so the horse doesn’t contact at the gullet lip.

|

|

| With the same gullet height, the hand hole height increases with greater stock thickness and drops with less stock thickness. | With the same hand hole height, the gullet height increases with less stock thickness and decreases with a greater stock thickness. |

3) Top cut angle

The top of the fork is cut at varying angles compared to the back of the fork. The greater the top cut angle, the greater the rise toward the gullet lip, all else being the same. However, this change is often made in combination with stock thickness changes so the fork doesn’t end up looking too downhill. In general, forks with greater stock thickness also have more top cut angle. Old time slick forks also had a greater top cut angle, necessitating a really tall gullet height to clear at the hand hole. This is generally what gives them that “old time” look compared to modern slick forks.

|

|

| With the same gullet height, the hand hole height increases with less top cut angle and drops with a greater top cut angle. | With the same hand hole height, the gullet height increases with more top cut angle and decreases with less top cut angle. |

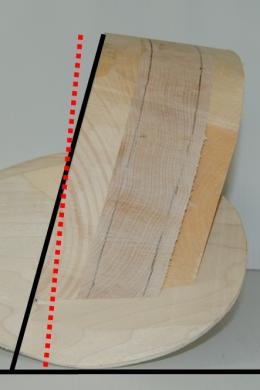

4) Fork angle

If you stand a fork up straighter compared to the bars and change nothing else, the front of the fork will rise compared to the back, almost to the point of being goofy looking. Therefore, when we stand a fork up, we also change the top cut angle. The end result on our trees is a hand hole height about 1/8” lower for the same gullet height when compared to the same fork leaned ahead our regular amount.

|

|

|

| Buster Welch fork leaned ahead | The effect of changing the fork angle. | Buster Welch fork stood up |

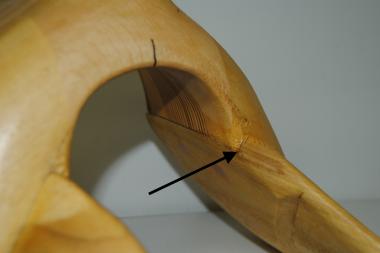

D) The unmeasured component - Gullet shape

A factor that can't be measured, yet is important in whether a fork contacts the withers or not, is the shape of the fork gullet. How thick is it, not just at the back of the fork but throughout the gullet? Does it bulge down quickly from the gullet lip or is it scooped out well to allow more clearance farther back even with the same hand hole and gullet measurements? Like many things when it comes to saddle trees, it is the shape along with the measurements that combine to make the tree not only aesthetically pleasing but functional as well.

|

|

| The shape of the gullet on our metal horn trees. | The shape of the gullet on our wood post horn trees. |

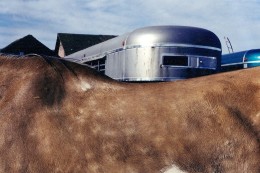

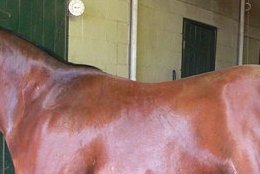

E) The horse factor

Regardless of the specs of the saddle, the conformation of the horse’s withers is crucial to whether it will contact or not. It is not just how tall or short the withers are, but how far back they go relative to the shoulder blades and therefore relative to where the gullet sits. The shape of the withers ultimately is what determines if the gullet height or the hand hole height is more important. A saddle will be used on many horses and you don’t know what all wither shapes will end up beneath your work. But saddles are built for a type of horse and wither conformation goes along with body type. Are you building for thoroughbred cross type of working horses with taller withers or bulldog horse types that have rounder withers? Knowing this is what helps you choose what specs you order.

|

|

|

F) Ordering “clearance”

Some owners think they need to order a really wide tree so it “sits right down” on the horse for roping. It is far better to order the bar specs to fit the horse properly and then lower the gullet by making a low arch on the fork. This accomplishes the goal of keeping the gullet close to the horse for roping and yet keeps the saddle fitting well.

As we have tried to explain, hand hole height is just as important, if not more important, than gullet height when it comes to not contacting the horse’s withers. We take orders by gullet height or hand hole height, whichever you prefer to give, and we can let you know what the other measurement will be depending on what fork style you order. If you order something that seems very high or, especially, very low we may check with you to make sure you understand what you will be getting.