We are no longer building saddle trees, but we have two videos about how Western saddles fit horses available on our westernsaddlefit.com website.

Construction Materials

Introduction

One of the most Frequently Asked Questions is “What woods do you use in your trees?” Here is a summary of the materials we use. For a more detailed look at how we build our trees, see the Building a Saddle Tree section of our website.

Wood types

We make every tree out of at least three different types of wood:

We make every tree out of at least three different types of wood:

1.) Yellow poplar, also called tulip wood, is an eastern hardwood. It is strong yet has some flexibility. In our “torture tests” we have found that this wood always splits longitudinally, not across the grain, which makes it ideal for use in the bars. (And since we have yet to have a tree come back broken, that says something for its strength!) We also use it in our cantles.

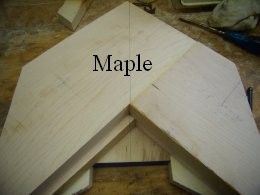

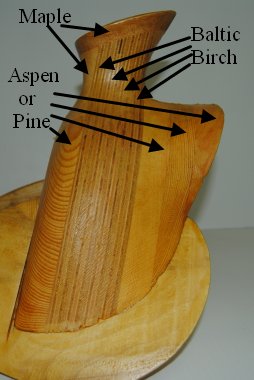

2.) A hardwood is used in the center of all forks. We use maple where we use solid wood. We will also use Baltic birch, which is plywood made totally of birch with 1/16” laminations, in the center of our forks and for the face of our cantles.

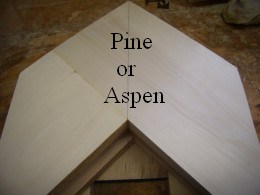

3.) A lighter wood is used in the parts of the fork that aren’t hardwood and for small pieces on the bars. These are places where strength isn’t as much of an issue. We use pine for these pieces.

Wood quality

All our wood is kiln dried to a furniture dry level, 10% or less. We go through lifts of limber to individually choose the boards we want to build our trees from. Since we mark and cut each piece individually, we can cut around any knots, using only clear wood in our trees. Occasionally small pin knots are unavoidable but they are always positioned in a non-stress area.

Bars

Because we don’t have a standard bar length, every pair of bars are all glued up at a specific length for individual orders. The yellow poplar is 2” thick, and there are two pieces of pine glued on to it where the two inches of poplar isn't quite thick enough - one just behind the fork cut, and one behind the cantle. We are confident in the strength of the wood we use so we use solid wood if we can get the width of wood we need. If not, we will laminate bars.

Metal Horn Forks

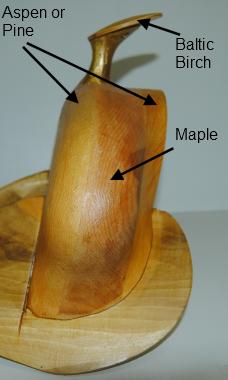

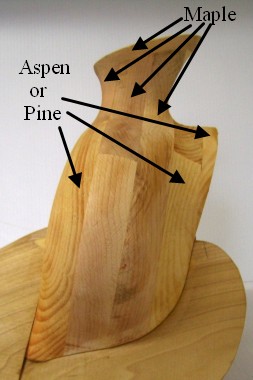

All metal horn forks have a solid 2” thick piece of hardwood (usually maple) in the center. This gives the strength you want in a fork and the screw holding ability you need to anchor the horn and the bars solidly to the fork. The front and back layers are made of two pieces of pine placed so the grain is 60 degrees to the vertical and glued together. Horn caps are made of Baltic Birch, a thinly laminated birch plywood, to avoid splitting.

All metal horn forks have a solid 2” thick piece of hardwood (usually maple) in the center. This gives the strength you want in a fork and the screw holding ability you need to anchor the horn and the bars solidly to the fork. The front and back layers are made of two pieces of pine placed so the grain is 60 degrees to the vertical and glued together. Horn caps are made of Baltic Birch, a thinly laminated birch plywood, to avoid splitting.

Wood Post Forks Using Solid Wood

The back layer of the fork has a 1” thick, 4” wide piece of hardwood with the grain running up and down in the center that makes up the back section of the horn. The pieces glued to the edges of the 4” wide hardwood are pine and are at a 60 degree angle. The next two layers are V shaped 1” thick sections of hardwood (usually maple). They are laminated with the grain at 90 degrees to each other, ending up at 45 degrees off the vertical. These grains run opposite to each other in the horn. We make the fourth layer like the first layer for trees with larger horns where the fourth layer ends up being in the horn as well. This construction ensures that entire horn is hardwood, with three different grain directions. For smaller horns where the fourth layer doesn’t end up in the horn, we use pine glued in the same configuration as layers two and three, as pictured. The fifth layer is made of two pieces of pine glued at the center with the grain 60 degrees to the vertical. Additional lip pieces are also pine. Horn caps are solid hardwood.

|

|

|

|

|

|

Wood Post Forks Using Baltic Birch

Instead of two layers of solid wood in the center of the fork, we will use 4 layers of ½” Baltic Birch. The rest of the fork is constructed the same.

Cantles

The cantles are made of four layers. The front two layers are half inch thick pieces of Baltic birch plywood. The third and fourth layers are one inch yellow poplar with the grain running horizontally. The Baltic birch takes the nails well without splitting, and the combination of these woods gives the strength needed. Plus, the cantles look really cool!

|

|

Horns

The metal horns we use are of bronze. We purchase our horns either from Herb Bork of Bork Saddlery Hardware in Oregon, or Boise Foundry in Idaho.

Putting It All Together

Once the fork and the cantle are shaped they are glued to the bars with waterproof wood glue (Titebond II Premium Wood Glue). Top quality screws (GRK Fasteners) are used to attach them to the bars – usually five each side on the fork and three each side on the cantle. The screw holes are filled with body filler which is sanded for a smooth finish. The tree is then varnished with three coats of marine (very water resistant) varnish.

|

|

Rawhide

We make our own rawhide from hides we get from the closest slaughterhouse. These hides are generally from bulls or occasionally large cows. If you request a lighter hide or a lighter weight tree we use the cow hide. We dehair and flesh it, then put it on the tree wet. The hide is not split.

We make our own rawhide from hides we get from the closest slaughterhouse. These hides are generally from bulls or occasionally large cows. If you request a lighter hide or a lighter weight tree we use the cow hide. We dehair and flesh it, then put it on the tree wet. The hide is not split.

Rawhiding

The tree is laced with deer rawhide lace that we make here from hides of local deer we get from hunters every fall. Stainless steel ring nails (5/8”) are used to tack the hide in place.

|

|

Drying and Finishing

The tree is dried for at least two weeks on a flat surface and weighted with 20+ pound weights when the rawhide is dry enough to tolerate them in order to keep them square as they dry. The seams are pounded up to twice a day as needed to make them lay flat, and the nails are reset daily as needed. Once dry, the tree gets two more coats of marine varnish before being sent out. This varnish has a matte finish that does not need to be scuffed for leather glues to bond well.

|

|

|